Product Description

PUSH BACK RACKING

PUSH BACK PALLET RACKING: ACHIEVE HIGH DENSITY FILO STORAGE

Effectively utilising floor and cubic space, Push Back Pallet Racking is amongst the most space and time-efficient racking storage systems available.

Push Back Pallet Racking allows you to double or triple your available storage space easily and cost-effectively. It is accessible using most types of lifting trucks.

Push Back Racking is space saving solution, designed to provide deep storage and automatically move pallets. Push back pallet racking works on the First-In Last-Out (FILO) method making it an ideal solution where stock rotation not required but speed and efficiency is.

What is Push Back Racking?

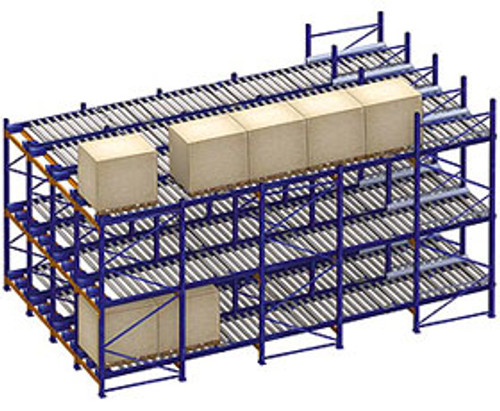

Push Back Pallet Racking is a flexible and cost-effective solution. Pallets are placed a "cart" which pushes the previous pallet into the next storage location. The process is repeated until storage is up to five pallets deep per lane, dramatically increasing storage capacity compared to Standard Pallet Racking.

A pushback racking system contains a pair of inclined rails and a series of nesting carts which ride on these rails. The first pallet is loaded on the first cart by a forklift. When the forklift comes in with the second pallet, the first pallet gets pushed back and the second pallet is placed on the next cart. This process is repeated until each lane is full.

To remove pallets, the forklift picks up the first pallet and backs out; The remaining pallets will flow to the front of the lane. Each pallet can be removed in succession until the lane is empty.

The last pallet to be loaded will be picked first and once picked the pallets in line behind will then move forward towards the picking face.

How Does Push Back Racking Work?

The racking structure has built in cart and rail system which is slightly inclined and slope towards the picking face. When a pallet is being loaded the cart and rail system allows the loading pallet to push the other pallets further back. The first pallet to be loaded will move further to the back as more pallets enter the lane. The system works on the first-in last-out (FILO) method. When a pallet is picked gravity allows the remaining pallets to move forward, gently assisted by the rollers and breaks.

What are the Benefits of Push Back Racking?

The Push Back system is quick to load and unload while stock rotation is improved. All levels are independent of one another, allowing quick and easy access to products

Pushback Racking is much faster to load and unload than Drive-In Racking because the pallets automatically move forward to the pick face facing the aisle. Rack damage is significantly reduced because the forklift does not have to drive into the rack to remove pallets.

Push-Back Pallet Racking is ideal for use when there are several pallets of the same item being stored.

- Bulk Storage

- Increase Efficiency

- Maximise the Cube

- Fast Access to Pallets

- Reduced Maintenance

- Great Space Utilization

- High Throughput Speed

- Eliminates unnecessary Aisles

- No specialised forklifts required

- FILO Principle (First In, Last Out)

- Each system is custom designed and manufactured

- Pallets stored in lanes ranging from 2 to 5 pallets deep

- Combines the benefits of Drive-In Racking with Live Pallet Racking Systems

Increased Safety:

The work of the forklift truck is minimised with less travel, less manoeuvring with only one aisle to navigate, on which pallets are clearly visible. This reduces the chance of collision and reduces the time spent on the working aisle. As the there is no need for the forklift truck to enter the structure, the chance of damage to the racking structure is minimised.

Easy to Integrate:

Push back pallet racking can be used for your entire facility or can be used in conjunction with other storage systems. As a deep racking system which only requires one aisle it can be placed in corners or against a wall, so it does not interfere with the rest of your operation and there’s no need to adjust your handling equipment to suit.

High Density Storage:

Push back pallet racking is one of the most popular solutions for those looking for a highly sophisticated compact storage solution for large volumes of SKUs. Loading and picking is carried out on the same single aisle so you can increase your storage by 75% by eliminating numerous aisles no longer required.

Easy and Safe Loading and Retrieval:

Loading and picking is simple and fast with clear visibility of the pallets. Because the pallets ready for picking sit at the front of the picking face they are easy to locate and pick.

No Specialist Handling Equipment Needed:

The system is perfectly suitable for standard forklift trucks so there is no need to purchase specialist trucks. This is useful for warehouses which currently use standard pallet racking systems and standard trucks.

Saves Time and Money Whilst Adding Value and Increasing Productivity:

With fewer aisles to navigate there is less time spent searching for specific pallets saving you time and money on labour. The loading and retrieval processes become optimised and more time efficient which in turn increases productivity. The ability to store more pallets with push back pallet racking within a specific area adds more value to your space and in turn reduces your per pallet costs.

What are the Disadvantages of Push Back Racking?

Decreased pallet selectivity.

Who Uses Push Back Racking?

There are a number of ideal applications for push back pallet rack systems. The system provides a high-density storage solution in a relatively small space since it only requires one aisle to load and unload.

Companies that store multiple pallets of the same SKU are a good candidate for push back racking. Each lane can hold a particular SKU, making picking more efficient.

Because of this high density, it is ideal for use in expensive real estate storage areas such as cooler or freezer environments.

Push back pallet racking is used across many industries including manufacturing, cosmetics, home ware, pharmaceutical as well as food and beverage. This smartly designed storage system is suited to any warehouse looking to maximise storage capacity allowing them to store large numbers of product with high turnover that do not require assisted stock rotation.

What considerations are there to keep in mind with Push Back Racking?

To ensure suitability examine your space before implementing a push back pallet racking system.

One side of the inclined structure will be higher at the top, so it is important that the ceiling is high enough to accommodate this. Take note of any potential obstacles including structural columns, sprinklers, and heating systems.

Consider pallets in terms of size and volume, and whether you will require direct access to every pallet at any given time. Access is quick and easy with push back pallet racking however, as a deep storage system this only applies to the pallets located at the frontal face of the system.

Is stock rotation a priority for your operations? Pallet live racking works in a similar way whilst using the first-in first-out (FIFO) method therefore provides assisted stock rotation.

What are the standard sizes of Push Back Racking?

Each system is custom-designed and manufactured to suit each client’s unique needs and environment. Each building is different, and no two warehouses work in the same way.

What is the general layout of Push Back Racking?

Push Back Racking will look like a cube or box within your warehouse. It will be a “block” that is several pallets deep, several pallets wide, and several pallets high. The exact size and specification will be determined based on a detailed needs analysis and site assessment.

What if Push Back Racking is not the right solution for me?

We pride ourselves on offering one of the largest ranges of racking in South Africa.

We will almost certainly be able to find something more suitable to your needs from one of the systems below:

- Mobile Racking

- Light Duty Racking

- Cantilever Racking

- Wide-Aisle Racking

- Adjustable Racking

- Double Deep Racking

- Very Narrow Aisle Racking

- Drive-In and Drive-Through Racking

- Carton Flow and Pallet Flow Racking

What areas do you deliver and install Push Back Racking in?

We deliver and install Push Back Racking systems throughout South Africa.

Our main service areas include (but are not limited to):

Gauteng (All Areas), Western Cape (All Areas), Kwazulu-Natal (All Areas), Nelspruit, Limpopo, Bloemfontein, Rustenburg, East London, Port Elizabeth.

At Dreymar Industrial, we aim to supply push back racking racking systems that are as unique as your business.

We aim to install our push back pallet rack systems with as little inconvenience to our clients as possible, using highly experienced, full-time installation teams.